Tile backer boards calculator

Create a Solid Foundation for Tiling – Tile Backer Boards Made Easy

Our Tile Backer Boards Calculator is here to streamline your tiling projects in bathrooms, kitchens, and wet rooms. Tile backer boards are essential for creating a stable, moisture-resistant substrate, ideal for spaces exposed to humidity and water. They prevent warping, reduce the risk of mold, and add insulation, making them an invaluable addition to any tiling project.

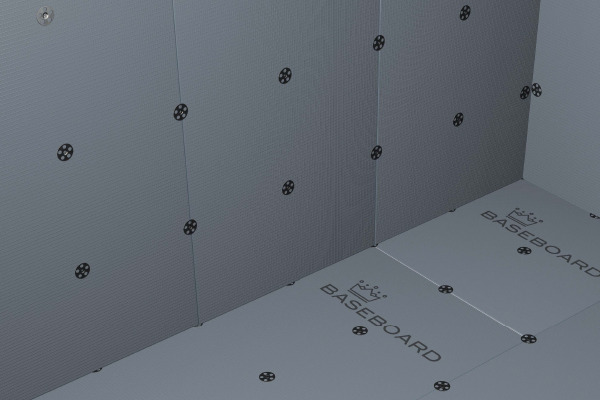

Unlike traditional materials like plywood or drywall, tile backer boards offer superior waterproofing and durability, protecting your investment and ensuring that your tiling stands the test of time. Our XPS cement-coated boards are specially designed to provide thermal insulation, structural support, and a long-lasting tiling surface.

Using the calculator is straightforward: simply enter your room dimensions, or if you already know the area, input it directly in square meters. You can also exclude certain areas, such as doors or shower trays, to avoid overestimating material needs. The calculator will provide tailored recommendations on the number and thickness of boards required, as well as additional accessories like washers and screws.

Once your calculations are complete, you’ll receive a comprehensive list of materials with options to adjust quantities, add items to your cart, or download the list as a PDF for future reference. Whether you’re a DIYer or a professional contractor, our Tile Backer Boards Calculator ensures you have everything you need to create a reliable, water-resistant surface ready for tiling.

Tile Backer Boards Options Explained

Wall Boards

Wall tile backer boards provide a sturdy, moisture-resistant base for tiles, ideal for areas exposed to water and humidity, such as bathrooms. Available in various thicknesses—6 mm, 10 mm, 12 mm, and 20 mm—these boards offer flexibility for different project requirements. Thinner boards, like 6 mm and 10 mm, are often preferred for walls due to their lighter weight, while thicker boards, such as 12 mm and 20 mm, are commonly used for floors to provide enhanced strength and stability. However, the choice of thickness can vary based on specific project needs and structural considerations.

Floor Boards

Floor tile backer boards are designed to withstand significant weight and resist moisture, providing a stable substrate for tiling on floors. With thickness options of 6 mm, 10 mm, 12 mm, and 20 mm, these boards enhance the longevity of tile installations in high-moisture environments and are compatible with underfloor heating systems. Thicker boards, such as 12 mm and 20 mm, are commonly used for floors to provide enhanced strength and stability. However, the choice of thickness can vary based on specific project needs and structural considerations.

Excluded Areas

When installing tile backer boards, it's essential to account for areas where installation is unnecessary or impractical. For walls, exclude regions occupied by doors, windows, or other fixtures, as these surfaces do not require tiling. On floors, avoid placing backer boards under elements like wet room trays or built-in furniture, where tiling isn't needed. Properly identifying and excluding these areas ensures efficient use of materials and a streamlined installation process.

Understanding Your Calculator Results

Using our Tile Backer Boards Calculator, you’ll receive a comprehensive overview to help you plan and install efficiently. Your results will include:

- Coverage Area: The total area to be covered, automatically adjusted to exclude any specified non-covered areas, such as doorways or shower trays.

- Product Recommendations: The recommended quantities and sizes of tile backer boards based on your specific room configuration and coverage requirements.

- Materials Needed: The number of boards, washers, and screws required to complete your project.

- Cost Estimate: An approximate total cost based on your selected options and room dimensions, helping you with clear budgeting.

Our calculator ensures you have a detailed plan for your tile backer board installation, so you’re fully prepared to proceed with confidence.

Advantages of Installing Tile Backer Boards

- Easy Installation: Lightweight and easy to cut, these boards simplify installation while maintaining high durability.

- Waterproof and Mold-Resistant: Ideal for wet areas, tile backer boards provide a waterproof surface, preventing moisture buildup and mold formation.

- Thermal Insulation: With excellent insulating properties, tile backer boards improve energy efficiency, especially when used with underfloor heating systems.

- Stable and Durable Substrate: Tile backer boards are highly resistant to warping or buckling, making them a superior substrate for tiling over plywood or drywall.

Why Choose XPS Cement-Coated Tile Backer Boards?

Our XPS cement-coated tile backer boards offer outstanding performance for tiling projects in wet areas like bathrooms and wet rooms. XPS (extruded polystyrene) boards are lightweight yet strong, providing excellent insulation and moisture resistance. The cement coating adds an extra layer of durability, making them an ideal choice for creating a stable, waterproof, and thermally efficient substrate for your tiles.

Unlike plywood or other substrate materials, XPS tile backer boards remain flat and stable, allowing for a consistent and level tile installation. They are resistant to water absorption, reducing the risk of mold or mildew growth and ensuring a long-lasting, hygienic surface.

What Are Tile Backer Boards?

Tile backer boards are specialized substrate materials designed for tiling. Unlike plywood, which can warp when exposed to moisture, backer boards maintain a hard, flat surface that won’t buckle or shift over time. This stability allows you to apply tiles using a thinset mortar, creating a level and reliable tile surface that stands up to moisture and temperature changes.

Applications: These boards are ideal for bathroom and wet room installations, as well as spaces with underfloor heating, due to their insulating properties. Tile backer boards help retain heat and improve the efficiency of underfloor heating systems, making them a practical choice for energy-conscious homes and projects.

XPS Cement-Coated Boards - Frequently Asked Questions

What are XPS cement-coated boards, and why are they used?

XPS cement-coated boards are a type of tile backer board made from extruded polystyrene foam coated with cement. They provide a waterproof, durable, and thermally insulating surface, ideal for tile installations in wet areas like showers, bathrooms, and areas with underfloor heating.

Why choose XPS boards over traditional backer materials?

XPS boards are lightweight, easy to cut, and highly resistant to moisture and mold. They offer strong thermal insulation, making them compatible with underfloor heating, unlike traditional materials such as plywood, which are prone to water damage and dimensional instability.

What thickness of XPS board should I use?

The appropriate thickness depends on the application. For floors, 6 mm thick boards are generally sufficient, while 10 mm thick boards provide added strength for stud walls or areas requiring extra rigidity.

Are XPS cement-coated boards suitable for wet areas?

Yes, XPS boards are designed for wet areas and provide a waterproof substrate. Their cement coating offers extra durability, and they resist water, preventing mold and rot. For best results in wet installations, seal joints between boards with a waterproofing kit.

Can I use XPS cement-coated boards with underfloor heating?

Yes, XPS boards are ideal for use with underfloor heating due to their thermal insulation properties. They help improve energy efficiency by directing heat upwards into the room rather than allowing it to dissipate into the substrate.

How do I install XPS cement-coated boards?

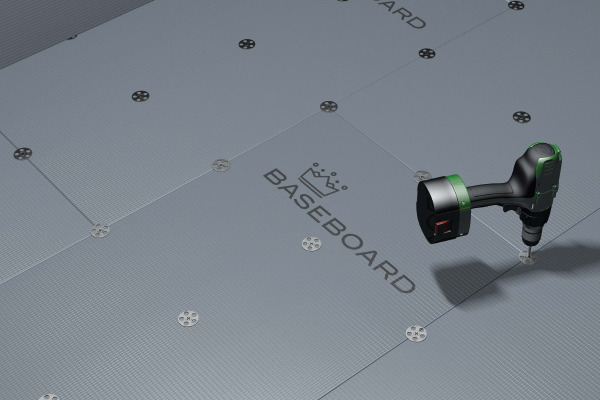

To install XPS boards, apply adhesive or screws and washers, depending on the substrate. For floors, ensure proper adhesive coverage and stagger board placement. For walls, ensure all edges are supported by studs or joists. Boards must always be laid in a staggered pattern to enhance stability and reduce movement.

Do I need to prime XPS cement-coated boards before tiling?

Yes, priming XPS boards before tiling enhances adhesive bonding and prevents moisture absorption. Use a diluted primer applied evenly, ensuring the surface is clean and dry for optimal tile adhesion.

How much weight can XPS cement-coated boards support?

XPS boards provide a stable surface that supports significant tile weight, sufficient for most interior tiles. Their cement coating adds additional load-bearing capacity compared to other foam-based backer boards, making them suitable for walls and floors in tiled areas.

How do I cut XPS cement-coated boards?

XPS boards are easy to cut using a utility knife or saw. Always score with a straight edge and snap for clean cuts. For more intricate shapes, a utility knife with a fresh blade works well.

Do I need to seal joints between XPS boards in wet areas?

Yes, when installing in wet areas like showers, joints between XPS boards should be sealed with a waterproofing or tanking kit. This step ensures a watertight barrier, preserving the boards’ moisture-resistant properties and preventing leaks.